Uttarakhand tunnel collapse: Auger drill machine emerges as heroic lifeline in rescue mission

As the rescue operation hinges on the success of the 'American auger' machine, the significance of this innovative approach cannot be overstated. Augers, once primarily associated with industrial efficiency, have now emerged as heroic tools capable of saving lives.

Highlights

- Initial attempts focused on traditional debris removal, but by the morning of 14 November, the rescue teams shifted strategy

- The game-changing moment arrived with the deployment of the 'American Auger' machine, airlifted from New Delhi

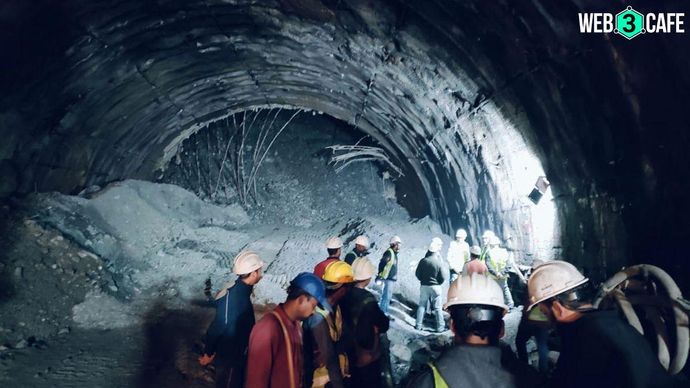

On 12 November, tragedy struck northern Uttarakhand as an under-construction tunnel collapsed, ensnaring 40 workers in a perilous situation.

The catastrophe unfolded in the Brahmakhal-Yamunotri national highway tunnel section between Silkyara and Dandalgaon. Forty workers found themselves trapped, prompting immediate rescue operations. Essential supplies of food and medicine were dispatched to sustain the workers, and ongoing communication aimed to uplift their spirits amid the challenging circumstances.

Initial attempts focused on traditional debris removal, but by the morning of 14 November, the rescue teams shifted strategy. A horizontal drilling platform was established to introduce a more efficient approach. This decision set the stage for a groundbreaking turn in the rescue mission.

The arrival of the 'American Auger' machine

The game-changing moment arrived with the deployment of the 'American Auger' machine, airlifted from New Delhi. This specialised equipment, capable of drilling through debris at a remarkable rate of 4-5 meters per hour, marked a turning point in the rescue operation. Transported in parts by Air Force Hercules aircraft, it was swiftly assembled and transported to the tunnel site through a green corridor.

Let's delve into the significance of this specialised equipment and understand the role it plays in the ongoing rescue mission.

Understanding the Auger drill machine

Simply put, an auger is a spiral-shaped tool designed for drilling holes into various surfaces or materials. The key component, known as "flighting," is a spiraling metal shaft with a blade at the end. The flighting rotates to scrape, cut, or siphon out drilled materials, allowing for efficient excavation. Augers come in various types, each tailored for specific materials or surfaces, and they can be powered electrically or manually.

Common uses of augers

Augers are primarily utilised for drilling holes in a variety of industrial applications. Whether for solar posts, telephone poles, or deck posts, augers prove invaluable in saving time and labor, enhancing workflow efficiency. These tools are widely used in construction sites and industrial projects to streamline operations and improve overall efficiency.

Augers vs. standard drills

Compared to traditional drill bits, augers offer several advantages. They provide greater drilling depth, ensure smooth and uniform holes, require less downward pressure for boring, and prevent clogging of holes due to efficient material evacuation. These features make augers particularly effective in challenging drilling scenarios.

Augers: Versatility and industrial significance

Augers come in various types, each tailored for specific drilling purposes. Whether powering through earth, grain, or ice, augers can be operated electrically, attached to a tractor, or manually by hand. Auger drill bit sizes range from 4 to 18 inches in diameter, with depths generally reaching 3 to 4 feet. However, an auger can drill as deep as 95 feet, with the option of adding an extension rod for greater depth.

This versatility makes augers a go-to tool for a wide range of drilling needs.

As the rescue operation hinges on the success of the 'American Auger' machine, the significance of this innovative approach cannot be overstated. Augers, once primarily associated with industrial efficiency, have now emerged as heroic tools capable of saving lives.

In the challenging terrain of Uttarakhand, this Auger machine serves as a beacon of hope for the trapped workers, emphasising the importance of technology and adaptability in overcoming crises.